Helping utilities reduce overflows faster, at lower cost, and with full confidence.

Dynamic control is transforming how utilities of all sizes manage wet-weather events.

The right platform can unlock hidden capacity in your network, accelerate overflow-reduction programs, and make sure every project dollar goes further.

But not all “real-time” or “digital twin” systems are capable of reducing overflows through dynamic control.

Some digital twin-informed systems help utilities not only use existing infrastructure more effectively but also optimize future construction—right-sizing storage, treatment, and conveyance assets before they’re built.

And if overflow-reduction facilities already exist, these systems can maximize their performance during storm events, ensuring every gallon of capacity counts.

Here’s what to look for when choosing a dynamic control platform that truly delivers.

💡 1. Start with Visibility — “Turn on the Lights”

Before you can control, you need to see.

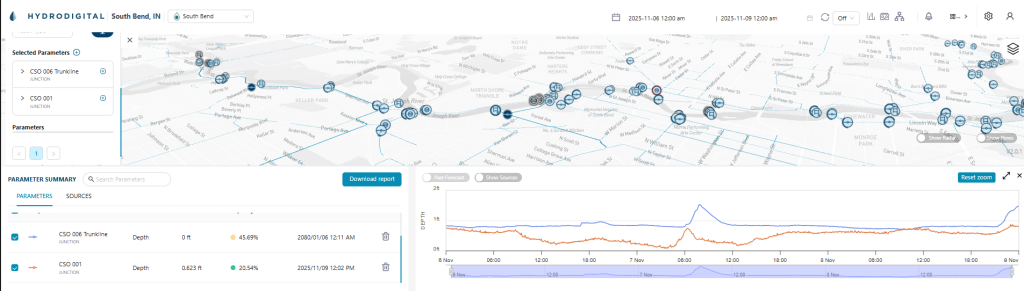

A strong platform should connect seamlessly to your existing sensors, SCADA, and GIS data to give you a real-time picture of your network — in one simple dashboard.

Modern systems can get you there in hours, not months.

Look for platforms that make integration easy, without requiring new infrastructure or complex rebuilds.

“The first step to smarter control is simply turning on the lights.”

🏗️ 2. Build on What You Already Have

Dynamic control isn’t about rebuilding — it’s about making better use of what’s already underground. The right platform helps you identify bottlenecks, underused pipes, and storage opportunities hidden in your existing system.

Even if your utility has only a few sensors or a simplified hydraulic model — or no model at all — that’s perfectly fine. A well-designed system can make use of every available asset. You can start small, even with a single level sensor or a rough model, and the platform will guide you on where new sensors add the most value and which parts of the model need calibration first.

By using existing assets more intelligently, utilities can reduce overflows quickly while cutting costs by 10x or more compared to traditional engineering approaches

🔮 3. Predict, Don’t Just React

True decision support means seeing what’s coming next.

Look for systems that combine real-time data, your hydraulic model, and accurate weather forecasts to create a digital twin that can predict how the network will behave before a storm hits.

That foresight lets operators make smarter, safer, and more effective control moves in real time.

“Forecasts become foresight — and foresight prevents overflows.”

⚙️ 4. Keep Control in Your Hands

Dynamic control shouldn’t mean losing control.

The best platforms are open, transparent, and designed so operators remain in charge.

✅ Choose between human-in-the-loop or automatic operation

✅ Implement logic directly in your SCADA if you prefer

✅ Update sensors, assets, and strategies on your own — no vendor lock-in

🌍 5. EXPERIENCE MATTERS

When it comes to dynamic control, experience isn’t just a nice-to-have — it’s essential. The technology only performs as well as the team that designs, configures, and supports it.

Look for partners who have decades of real-world experience implementing real-time control systems for utilities that can deliver value — not just building dashboards or analytics tools. The right team should understand both the technical side (models, data, automation) and the operational realities of running a sewer network in all weather conditions.

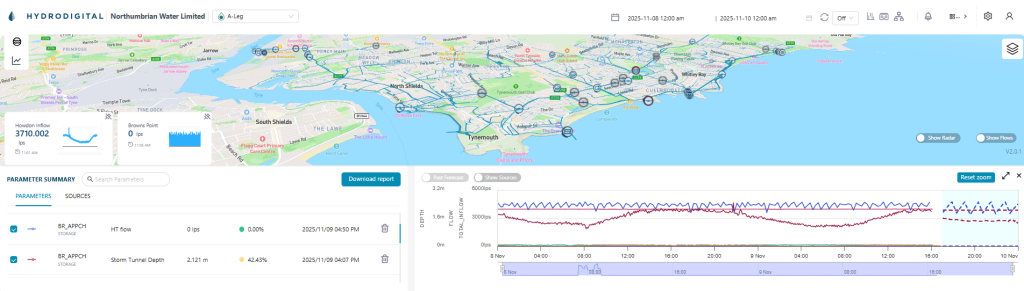

These results showcase what’s achievable when digital twins and dynamic control are applied by an experienced team—not just advanced software.

For example, our team helped South Bend avoid nearly $500 million in capital costs by using real-time control to reshape its CSO program in 2008. Our team did it again with, Buffalo, NY ($145M), Kansas City, MO ($1B), Cincinnati, OH ($40M). For the last 20+ years, our team has helped dozens of utilities save billions of dollars. Today, under the HydroDigital banner and with our current platform, we’re helping Northumbrian Water cut more than 75 million gallons of overflows during a typical 1- to 2-month storm event. Achieving the same reduction through traditional engineering would cost roughly $1 billion.

Ask potential providers:

☑️ Have they successfully delivered live dynamic control systems, not just pilots?

☑️ Do they have experience across different network types and regulatory environments?

☑️ Can they demonstrate measurable, lasting performance improvements from their past projects?

“It’s not just about what the platform can do — it’s about who stands behind it.”

🔐 6. Prioritize Security and Safety

Your real-time control system is part of your critical infrastructure — it must be built with security at its core.

Look for solutions aligned with ISO 27001 and NIST cybersecurity frameworks, featuring:

🔒 Encrypted data transfer and storage

🔒 Multi-factor authentication

🔒 Secure development lifecycle practices

Safety also means redundancy: manual overrides, fallback sensors, and fail-safe logic ensure that in the worst case, your system behaves exactly as before dynamic control.

🚀 The Bottom Line

The right platform helps utilities:

✅ Reduce overflows faster using existing assets

✅ Lower costs dramatically compared to traditional upgrades

✅ Operate confidently and safely in real time

It’s not just about technology — it’s about trust, transparency, and empowering operators to do more with less.

💬 Ready to Explore Dynamic Control?

HydroDigital’s open, glass-box platform is helping utilities worldwide Turn Data into Smarter Sewers.

Let’s explore how it could work for your system. Get in touch with us below!